The TRUTH of LED Display

Thermal System Management REAL Costs

-

Brendan O.

- LED Display

Advanced Thermal Management Systems

Our focus lies in the exploration of cutting-edge energy-efficient technologies achieved through the implementation of advanced thermal management systems for precise internal temperature regulation. Throughout this piece, we will delve into three distinctive types of thermal management systems meticulously tailored for LED displays:

Heat Sinks and Heat Pipes: These passive cooling solutions utilize metallic heat sinks and heat pipes to dissipate heat efficiently and maintain optimal operating temperatures.

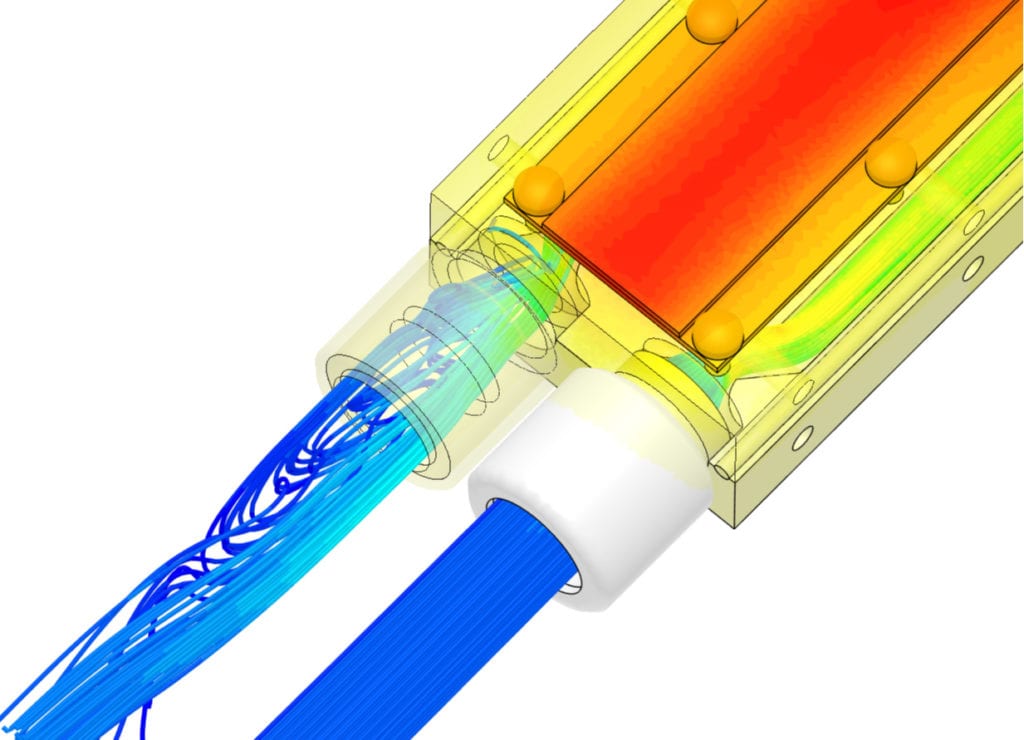

Liquid Cooling Solutions: Employing liquid-based cooling mechanisms, this system utilizes coolant circulation to effectively regulate temperature and enhance overall performance.

Active Thermal Control: By utilizing active cooling methods such as fans or thermoelectric coolers, this system actively manages temperature fluctuations, ensuring optimal functionality and prolonged lifespan.

Moreover, we will provide an in-depth cost breakdown for each system, considering initial investment, operational expenses, and long-term maintenance. Additionally, we will conduct a comprehensive analysis of the pros and cons associated with each thermal management system. Join us as we delve into the promising developments that are shaping the ever-evolving landscape of LED displays.

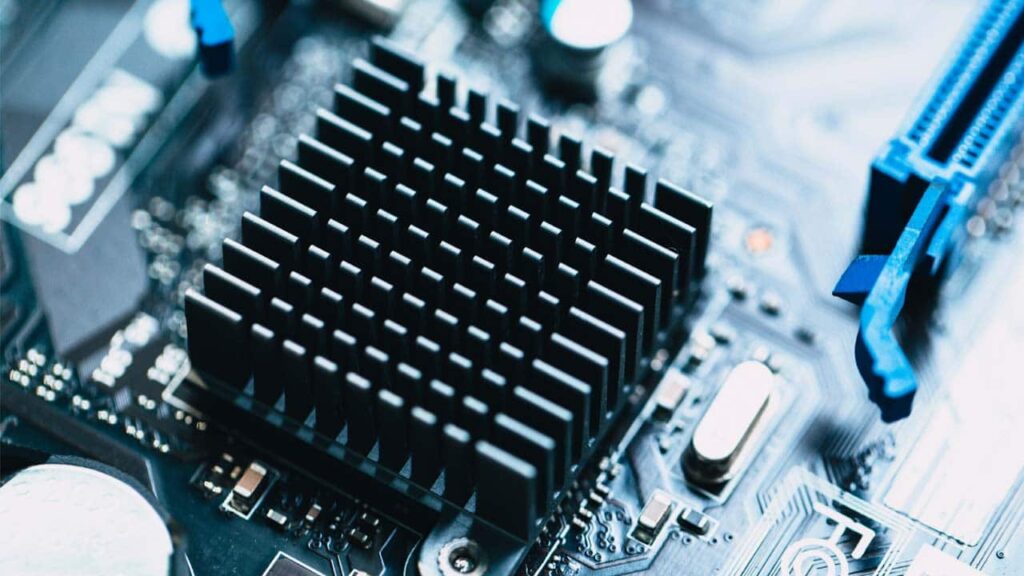

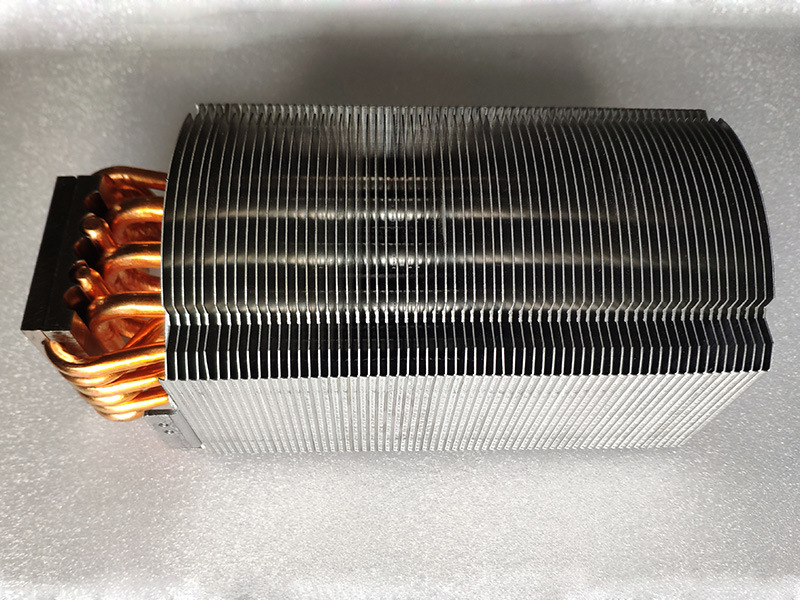

1.Heat Sinks & Heat Pipes

Heat sinks made of thermally conductive materials are commonly used in LED displays to dissipate heat away from the components. Heat pipes, on the other hand, are highly efficient heat transfer devices that use a combination of evaporation and condensation to transport heat away from the source. By incorporating heat sinks and heat pipes, LED displays can maintain lower operating temperatures, reducing energy consumption and enhancing overall performance.

Cost Breakdown:

- Heat Sink: The cost of a heat sink can vary depending on the material, size, and complexity. On average, the cost can range from $10 to $50 per unit.

- Heat Pipes: The cost of heat pipes depends on factors like length, diameter, and thermal performance. The cost can range from $5 to $30 per unit.

Pros:

- Relatively lower cost compared to other advanced thermal management systems.

- Simple installation and maintenance.

- Effective heat dissipation from critical components.

- No additional power consumption.

Cons:

- Limited heat dissipation capacity compared to liquid cooling solutions.

- May require additional fans or airflow for optimal performance.

- Heat sinks can occupy additional space within the display design.

2. Liquid Cooling Solutions

Liquid cooling systems are gaining traction in the LED display industry. These systems utilize liquid coolant to absorb heat from critical components, ensuring efficient heat dissipation. By directly cooling the heat-generating elements, liquid cooling solutions offer superior thermal management, enabling LED displays to operate at lower temperatures while maintaining optimal performance.

Cost Breakdown:

- Cooling System Components: The cost of liquid cooling components, including pumps, tubing, coolant, and reservoirs, can range from $50 to $200, depending on the complexity and quality.

- Heat Exchanger: The cost of a heat exchanger can range from $20 to $100, depending on size and efficiency.

Pros:

- Efficient heat dissipation, enabling lower operating temperatures.

- Enhanced thermal management for high-performance displays.

- Reduced risk of thermal throttling and component failure.

- Can accommodate higher power and heat loads.

- Suitable for larger display sizes and densely packed components.

Cons:

- Relatively higher cost compared to heat sinks and heat pipes.

- Requires additional components and installation complexity.

- Regular maintenance and monitoring of the liquid cooling system.

- Possibility of coolant leaks, although rare with proper installation.

3. Active Thermal Control

Advanced thermal management systems employ active thermal control mechanisms to monitor and regulate the display’s internal temperature. By using sensors and intelligent algorithms, these systems adjust cooling mechanisms in real-time, optimizing energy consumption based on the display’s operational requirements. This dynamic temperature regulation prevents excessive energy usage and minimizes thermal stress on the components.

Cost Breakdown:

- Temperature Sensors: The cost of temperature sensors can range from $1 to $10 per unit, depending on the type and accuracy.

- Control System: The cost of a control system can vary significantly based on complexity, features, and integration requirements. It can range from $50 to several hundred dollars.

Pros:

- Real-time temperature monitoring and dynamic adjustments.

- Efficient energy usage based on actual temperature requirements.

- Optimal thermal management for varying workload conditions.

- Can be integrated with existing display control systems.

Cons:

- Additional cost for sensors and control systems.

- Requires proper calibration and setup for accurate temperature monitoring.

- Initial setup and programming complexity.

- Potential for system failure if sensors or control systems malfunction.

Overall, the cost breakdown and pros/cons comparison indicate that heat sinks and heat pipes offer a cost-effective solution with effective heat dissipation, but with limitations in terms of heat dissipation capacity. Liquid cooling solutions provide efficient thermal management, especially for high-performance displays, but come with higher upfront costs and maintenance requirements. Active thermal control offers precise temperature regulation but involves additional expenses for sensors and control systems.

The choice of an advanced thermal management system for LED displays depends on factors such as display size, power requirements, heat load, and budget. Manufacturers need to consider their specific needs and trade-offs between cost, performance, and maintenance to determine the most suitable solution for their LED display applications.

Benefits and Future Outlook:

Implementing advanced thermal management systems in LED displays brings several benefits, including:

a) Enhanced Energy Efficiency: By effectively regulating internal temperatures, advanced thermal management systems significantly reduce energy consumption, leading to cost savings and environmental benefits.

b) Extended Lifespan: Maintaining lower operating temperatures through efficient thermal management ensures the longevity of LED displays. This not only reduces the need for frequent replacements but also contributes to sustainability efforts.

c) Improved Performance: Optimal temperature control prevents thermal throttling, allowing LED displays to operate at their peak performance levels consistently.

Looking ahead, the future of LED displays holds promising advancements in thermal management systems. Emerging technologies such as phase-change materials, graphene-based heat sinks, and miniature liquid cooling solutions are being explored to further enhance energy efficiency and address the increasing demands for higher resolution and larger display sizes.

LED displays have revolutionized the visual experience and energy efficiency in the display industry. Advanced thermal management systems play a vital role in optimizing energy consumption by regulating internal temperatures, ensuring long-lasting performance. As technology continues to evolve, the future of LED

Brendan O.

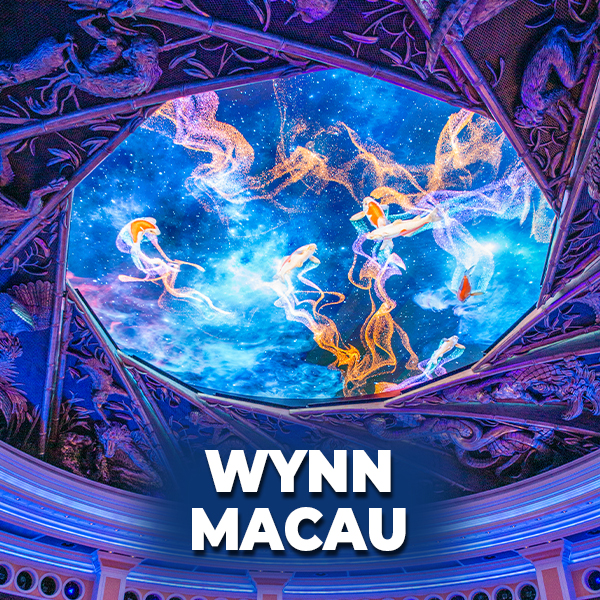

Who We Are

Pledco is a global reputable LED display design, engineering and manufacturer from North America, with our very own state-of-the-art production factory based in Asia. We pride ourselves on being the leading manufacturer for custom LED displays & UHD LED screens to Fortune 500 companies in over 30 countries.

WhatWe Do

We bring visual creativity to life; continually pushing the endless possibilities. From transparent mesh curtains overlaying corporate skyscrapers, to LED-wrapped vehicles, to concave video walls in newsrooms, to outdoor digital signs composed of 3D shapes; if you can envision it, our LED engineers can design, engineer and manufacture it.

How We Do It

Client’s approach us daily with “impossible” projects in terms of production and integration. At Pledco we take your design concept and apply our world-class engineering to bring your idea to life. The art of custom LED display dances in the details, and our extensive experience with custom client projects is hard to deny.

Our Customized Projects

A global reputable LED display design, engineering and manufacturer based in North America, with our very own state-of-the-art factory based in Asia. We pride ourselves on being the leading manufacturer for custom design LED displays & Ultra High Definition LED screens to Fortune 500 companies in over 30 countries.