Top 10 Issues: Indoor LED Displays

-

Brendan O.

- LED Display

In this technical blog post, we will discuss the top 10 issues that should be taken into consideration when using indoor LED displays. By understanding these issues, one can optimize the usage of indoor LED displays and minimize any potential problems.

1. Temperature & Humidity

Indoor LED displays are designed to operate within a specific range of temperatures and humidity levels. Deviations from this range can cause the display to malfunction or even fail completely.

This can be particularly problematic in environments such as airports or shopping centers, where the temperature and humidity levels fluctuate frequently.

Typically Indoor LEDs are prone to humidity issues and over the years this can lead to pixel failure, so by using high brightness outdoor LEDs it will protect the screens against any major humidity issues that usually produce condensation and in turn begin to deteriorate the wire connectors in the LEDs, however, the cost difference can be nearly four times the price when compared to the cheapest LEDs available in the market.

Buyers must be aware of the potential issues that can arise from purchasing the wrong type of LED for indoor projects.

2. Physical Damage

Indoor LED displays are electronic devices that are used to display various types of information such as text, images, and videos. They are composed of multiple small individual LED lights that work together to create the display. These individual LEDs are very sensitive and can be easily damaged if the display is bumped, knocked or dropped.

Moreover, the delicate electronic components of indoor LED displays are susceptible to damage from dust, dirt, or other contaminants. Exposure to these contaminants can cause issues like flickering, dead pixels, or reduced brightness in the display. The electronic components are also vulnerable to moisture, high temperatures, and voltage spikes, which can cause permanent damage to the display.

It is crucial to handle indoor LED displays with care to ensure that they remain in good working condition. It is recommended to avoid touching the display surface directly and use a soft cloth to clean it instead.

It is also important to avoid exposing the display to harsh environmental conditions and to make sure it is installed and maintained correctly. Regular maintenance and cleaning can help extend the lifespan of an indoor LED display and ensure that it continues to function optimally

3. Software Problems

Indoor LED displays, like any other digital device, can experience malfunctions that can affect their proper functioning. There are several reasons why indoor LED displays can malfunction, and these include software bugs, hacking, or malware infections.

Software bugs are common issues that arise due to errors in the programming code. Such bugs can cause the display to freeze, flicker, or show errors that prevent the device from functioning correctly. Hacking, on the other hand, involves unauthorized access to the display’s system, which can lead to data theft or alteration of the device’s programming code. Malware infections, which occur when malicious software is installed on the device, can also cause similar issues.

To prevent these problems, regular maintenance and software updates are essential. Regular maintenance involves routine cleaning and inspection of the display’s hardware and software components. Software updates, on the other hand, include the installation of the latest software patches and security updates, which can help to address known vulnerabilities and bugs in the system.

4. Power Surges & Voltage

One of the major issues with indoor LED displays is their vulnerability to power surges and voltage fluctuations. A power surge is a sudden, brief increase in voltage that can occur due to lightning strikes, utility company equipment failure, or other external factors. Voltage fluctuations, on the other hand, are small changes in voltage that can occur due to fluctuations in the power supply or changes in electrical loads.

When a power surge or voltage fluctuation occurs, it can cause damage to the electronic components of the LED display, such as the control board or the power supply. This damage can cause the display to malfunction or even fail completely. In some cases, the damage may be irreversible, requiring the display to be replaced entirely.

This issue is particularly problematic in areas that are prone to power outages or other electrical disturbances. If the power supply is interrupted, the LED display may not be able to function properly when power is restored, leading to further damage.

To mitigate the risk of power surges and voltage fluctuations, it is important to use surge protectors and voltage stabilizers with indoor LED displays. These devices can help regulate the power supply and protect the display from damage. Additionally, regular maintenance and inspection of the display can help identify potential issues before they cause major problems.

5. Brightness & Color Uniformity

Over time, the LED lights that make up the display can experience wear and tear, leading to a decrease in brightness or unevenness in color.

Environmental factors such as dust, dirt, and humidity can also affect the performance of LED displays. These factors can cause buildup on the LED lights, which can cause a reduction in brightness and color quality.

If left unaddressed, these issues can impact the overall quality of the image displayed on the LED screen, leading to a subpar viewing experience. To prevent this, regular maintenance and cleaning are essential.

Maintenance involves regularly checking the LED display for any potential issues such as burned-out lights or faulty components. Cleaning the screen involves removing any accumulated dust or debris using specialized cleaning equipment or solutions. This process ensures that the LED display is operating at its optimal level and maintains its intended brightness and color quality.

6. Viewing Angle

Over time, the LED lights on indoor displays can become less bright or change color due to aging or external factors like humidity or temperature. This can lead to an uneven distribution of light and affect the overall quality of the image or text displayed on the screen.

To prevent these issues and maintain the quality of indoor LED displays, regular maintenance and cleaning are necessary. Maintenance can include replacing or repairing damaged LED lights, checking electrical connections, and monitoring the device’s overall performance. Cleaning can involve removing dust, dirt, or other debris from the screen surface, which can accumulate and affect the display’s brightness and color.

Overall, regular maintenance and cleaning of indoor LED displays can help to ensure that the display performs optimally and produces high-quality images or text that is clear, bright, and consistent.

7. Burn-In

8. Calibration

To ensure that an indoor LED display performs at its best, it’s important to calibrate it properly.

Calibration involves adjusting the display’s settings to achieve accurate and consistent color reproduction, brightness, and contrast. This process is critical for ensuring that the display presents images and videos as intended, with accurate colors and a high level of detail. Calibration can also help reduce image distortion, ensure uniformity across the display, and optimize energy consumption.

When it comes to factory acceptance tests (FATs), calibration is a key step in ensuring that the display meets the required specifications and performance standards. A FAT is a process of testing and verifying that a product or system meets the requirements and specifications agreed upon between the customer and the manufacturer. A properly calibrated LED display is essential to passing a FAT, as it ensures that the display is performing as intended.

There are several reasons why it is important to perform calibration before a FAT. Firstly, calibration helps ensure that the display meets the customer’s expectations and requirements. If the display is not calibrated correctly, it may not present images or videos accurately, which could lead to dissatisfaction or complaints from the customer. This could result in delays or additional costs for the manufacturer.

Calibration is important for maintaining the display’s lifespan and reducing maintenance costs. A poorly calibrated display may consume more power than necessary, which can lead to higher energy costs over time. Additionally, if the display is not calibrated correctly, it may require more frequent maintenance and repairs, which can be costly and time-consuming.

9. Heat dissipation

One of the most important factors to consider when using an indoor LED display is heat dissipation. If not managed properly, the heat generated by the LEDs can lead to severe, long-lasting issues with your display.

Here are some reasons why proper heat dissipation is important for indoor LED displays:

- Prolongs LED lifespan: High temperatures can cause the LED chips to degrade faster, leading to reduced brightness and color shift. Effective heat dissipation ensures that the LED chips operate at a suitable temperature, which prolongs their lifespan.

Prevents power supply failure: High temperatures can also damage the power supply, causing it to fail prematurely. Proper heat dissipation helps to keep the power supply cool, reducing the likelihood of failure.

Reduces maintenance costs: A poorly cooled LED display may require more frequent maintenance due to damaged components. This can increase costs associated with repairing or replacing damaged parts.

Avoids safety hazards: High temperatures can pose safety hazards to users, such as causing the enclosure to become hot to the touch. This can lead to burns or other accidents if not properly addressed.

To effectively manage heat dissipation, you should consider the following:

Ensure proper ventilation: Proper ventilation ensures that cool air can enter and hot air can exit the display enclosure, reducing the temperature inside.

Use thermal management materials: Heat-conducting materials, such as thermal pads or heat sinks, can effectively dissipate heat away from the LED chips.

Control ambient temperature: Maintaining an ambient temperature between 20-25°C is optimal for indoor LED displays. Higher ambient temperatures may require additional cooling measures to prevent overheating.

In conclusion, managing heat dissipation is crucial for indoor LED displays to ensure optimal performance, reduce maintenance costs, and avoid safety hazards. Proper ventilation, thermal management materials, and controlling ambient temperature are key factors to consider in managing heat dissipation.

10. Interference

The issue of signal interference can pose a significant threat to the proper functioning of indoor LED displays if not managed correctly.

Signal interference occurs when electromagnetic radiation from various sources disrupts the signals being transmitted to the LED display, leading to distorted or poor quality visuals. This interference can arise from a variety of sources, including wireless devices, electrical wiring, and other electronic equipment that emits electromagnetic radiation.

The importance of managing indoor LED display signal interference issues cannot be overstated. If not addressed, it can lead to significant long-lasting problems with the display, including reduced image quality, ghosting, and even complete failure. This can result in lost revenue and decreased customer satisfaction, especially in environments where the display is a critical component of the business operation.

To avoid these issues, several measures can be taken to manage indoor LED display signal interference. One of the most effective ways is to ensure that the display’s installation and wiring are done correctly. This involves grounding the LED display and using proper cabling to reduce signal loss and interference.

Additionally, it is important to ensure that the LED display is shielded from any electromagnetic radiation sources such as wireless devices and other electronic equipment. Shielding the display can be done using specialized materials that absorb or reflect the electromagnetic radiation.

In conclusion, indoor LED displays are an essential component of many businesses and public spaces. However, signal interference issues can pose a significant threat to their proper functioning if not managed correctly. It is, therefore, crucial to take the necessary measures to manage signal interference and ensure the longevity and optimal performance of the LED display.

Popular Articles

Brendan O.

Who We Are

Pledco is a global reputable LED display design, engineering and manufacturer from North America, with our very own state-of-the-art production factory based in Asia. We pride ourselves on being the leading manufacturer for custom LED displays & UHD LED screens to Fortune 500 companies in over 30 countries.

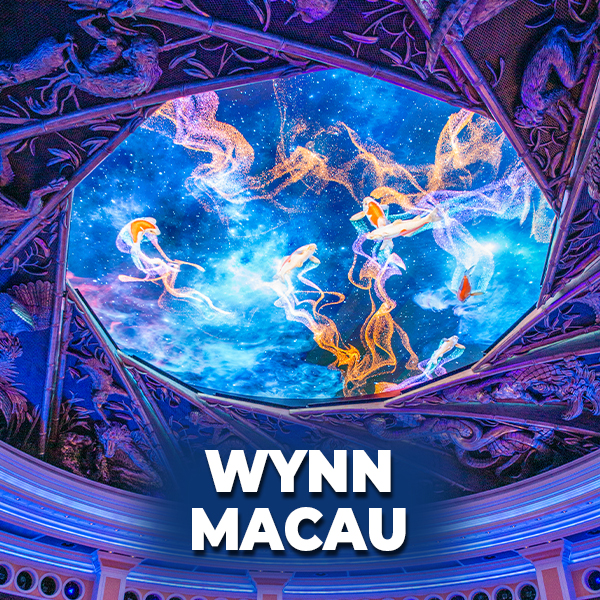

WhatWe Do

We bring visual creativity to life; continually pushing the endless possibilities. From transparent mesh curtains overlaying corporate skyscrapers, to LED-wrapped vehicles, to concave video walls in newsrooms, to outdoor digital signs composed of 3D shapes; if you can envision it, our LED engineers can design, engineer and manufacture it.

How We Do It

Client’s approach us daily with “impossible” projects in terms of production and integration. At Pledco we take your design concept and apply our world-class engineering to bring your idea to life. The art of custom LED display dances in the details, and our extensive experience with custom client projects is hard to deny.

Our Customized Projects

A global reputable LED display design, engineering and manufacturer based in North America, with our very own state-of-the-art factory based in Asia. We pride ourselves on being the leading manufacturer for custom design LED displays & Ultra High Definition LED screens to Fortune 500 companies in over 30 countries.