Pros & Cons: Gold vs. Copper Wire LEDs

-

Brendan O.

- LED Quality

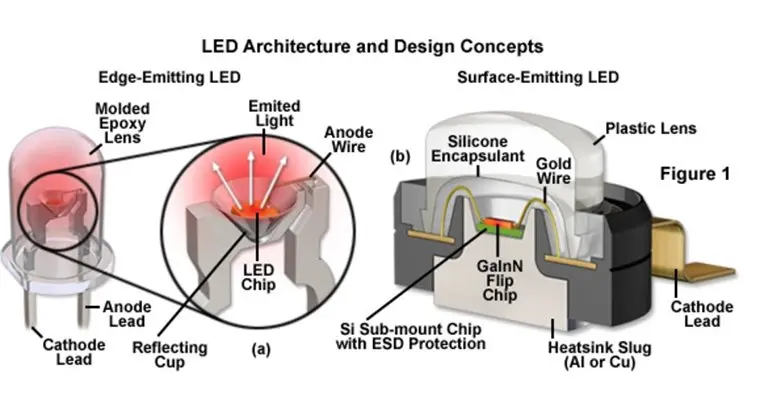

LED chips are small electronic components that produce light and are used in a variety of lighting applications, including LED display, street lighting, home lighting, and automotive lighting. LED chips can be made from different materials, including gold wire and copper wire, and each has its own unique characteristics and benefits.

In this article, we will explore the differences in quality between gold wire and copper wire LED chips and discuss the pros and cons of each.

1. Gold Wire LED Chips

Gold wire LED chips are made from a thin gold wire that is used to connect the LED chip to the circuit board. The gold wire provides a high-quality connection between the LED chip and the circuit board, which ensures that the LED chip is able to produce a stable and consistent light output. The gold wire also helps to protect the LED chip from corrosion, as gold is a very stable and non-reactive metal.

PROs

Durability: Gold wire LED chips are highly durable and can last for many years without needing to be replaced.

Efficient: Gold wire LED chips are very efficient and produce a bright and stable light output.

Low resistance: Gold wire LED chips have a low resistance, which helps to reduce the risk of electrical shorts and improves overall performance.

CONs

Cost: Gold wire LED chips are more expensive than copper wire LED chips due to the cost of the gold wire.

Complexity: Gold wire LED chips are more complex to manufacture than copper wire LED chips, which can increase the cost and time required to produce them.

2. Copper Wire LED Chips

Copper wire LED chips are made from a copper wire that is used to connect the LED chip to the circuit board. Copper wire is a good conductor of electricity and is relatively cheap, making it an attractive option for many manufacturers. Copper wire LED chips are typically less expensive than gold wire LED chips, but they do have some disadvantages.

PROs

Cost: Copper wire LED chips are cheaper than gold wire LED chips, making them a more affordable option for many consumers.

Easy to manufacture: Copper wire LED chips are easier to manufacture than gold wire LED chips, which can reduce the cost and time required to produce them.

Cost: Copper wire LED chips are cheaper than gold wire LED chips, making them a more affordable option for many consumers.

Easy to manufacture: Copper wire LED chips are easier to manufacture than gold wire LED chips, which can reduce the cost and time required to produce them.

CONs

Durability: Copper wire LED chips are less durable than gold wire LED chips and may need to be replaced more frequently.

Corrosion: Copper wire is more susceptible to corrosion than gold wire, which can affect the performance of the LED chip over time.

Resistance: Copper wire has a higher resistance than gold wire, which can affect the performance of the LED chip and increase the risk of electrical shorts.

Conclusion

Gold wire and copper wire LED chips each have their own unique benefits and disadvantages. Gold wire LED chips are more durable and efficient than copper wire LED chips, but they are also more expensive. Copper wire LED chips are cheaper and easier to manufacture, but they are less durable and have a higher resistance than gold wire LED chips. Ultimately, the choice between gold wire and copper wire LED chips will depend on your specific needs and budget.

Popular Articles

Brendan O.

Who We Are

Pledco is a global reputable LED display design, engineering and manufacturer from North America, with our very own state-of-the-art production factory based in Asia. We pride ourselves on being the leading manufacturer for custom LED displays & UHD LED screens to Fortune 500 companies in over 30 countries.

WhatWe Do

We bring visual creativity to life; continually pushing the endless possibilities. From transparent mesh curtains overlaying corporate skyscrapers, to LED-wrapped vehicles, to concave video walls in newsrooms, to outdoor digital signs composed of 3D shapes; if you can envision it, our LED engineers can design, engineer and manufacture it.

How We Do It

Client’s approach us daily with “impossible” projects in terms of production and integration. At Pledco we take your design concept and apply our world-class engineering to bring your idea to life. The art of custom LED display dances in the details, and our extensive experience with custom client projects is hard to deny.

Our Customized Projects

A global reputable LED display design, engineering and manufacturer based in North America, with our very own state-of-the-art factory based in Asia. We pride ourselves on being the leading manufacturer for custom design LED displays & Ultra High Definition LED screens to Fortune 500 companies in over 30 countries.