Top 5 LED Calibration Features of

The Minolta CS-200

-

Brendan O.

- Calibration

The Minolta CS 200 chroma meter is a device that is used to accurately measure and calibrate the color of LED displays. It is a powerful tool that offers many benefits to users, making it a popular choice for professionals and enthusiasts alike.

In this article, we will take an in-depth look at the Minolta CS 200 chroma meter and explore its features, capabilities, and advantages.

1. High Accuracy

The Minolta CS 200 is a specialized instrument designed to measure the color of LED displays with high accuracy. It achieves this by using a highly sensitive sensor that can detect and measure a wide range of colors. The colorimeter is capable of measuring both standard and extended color spaces, which means it can accurately capture a wide spectrum of colors.

Standard color spaces, such as sRGB and Adobe RGB, are commonly used in photography and digital media. On the other hand, extended color spaces like DCI-P3 and BT.2020 are used in high-end displays such as HDR TVs and cinema projectors. The Minolta CS 200 can accurately measure colors in both types of color spaces, making it a versatile tool for professionals and enthusiasts.

The CS 200 colorimeter is especially useful for individuals who require consistent and accurate color reproduction on their LED displays. For instance, graphic designers, photographers, and video editors require precise color calibration to ensure that their work looks accurate and consistent across different displays. The Minolta CS 200 enables them to achieve this by providing them with accurate measurements of the colors displayed on their screens.

2. Multiple Measurement Modes

The Minolta CS 200 is a color measurement instrument that provides multiple measurement modes to accommodate different measurement requirements. The instrument has three primary modes of operation, namely single measurement mode, average measurement mode, and continuous measurement mode.

In the single measurement mode, the instrument takes a single measurement of the sample, which is ideal for obtaining quick measurements of small areas. This mode is particularly useful for applications where time is of the essence, or when only a small area needs to be measured.

In contrast, the average measurement mode provides a more accurate measurement of larger areas by averaging multiple measurements taken across the area. This mode is ideal for measuring color variations across large surfaces and ensures that the measurement is representative of the entire area, rather than just a small portion.

The continuous measurement mode is used to monitor color consistency over a period of time. The instrument takes measurements at regular intervals, allowing users to observe any changes in color that may occur over time. This mode is particularly useful for applications such as printing or painting, where color consistency is critical, and any variation can result in costly rework.

3. Fast Measurement

One of its most notable features is its fast measurement capabilities, which make it a valuable tool for professionals who need to take multiple measurements in a short amount of time.

With its high-speed measurement technology, the Minolta CS 200 can quickly and accurately measure the color and brightness of various materials, such as paper, plastic, textiles, and coatings. This means that users can get reliable and consistent readings without spending too much time on each measurement.

The Minolta CS 200 can measure color and brightness in various modes, including spot, multi-point, and average measurements. This versatility allows users to choose the most appropriate measurement method for their specific needs, whether they need to measure small or large areas, or a combination of both.

The fast measurement capabilities of the Minolta CS 200 not only save time but also increase efficiency, as users can get more work done in less time. This can be particularly useful in industries such as printing, where color accuracy is critical, and time is often of the essence.

4. Auto-Calibration

One of its most notable features is its multiple auto-calibration capabilities. Auto-calibration is a process that involves adjusting the device’s settings to ensure accurate and consistent measurements over time.

The Minolta CS 200 has an advanced auto-calibration system that can automatically adjust the device’s settings to compensate for changes in temperature, humidity, and other environmental factors that can affect color measurement accuracy. This feature eliminates the need for manual adjustments and ensures that the device’s readings are consistent and reliable.

This multiple auto-calibration feature is particularly useful for professionals who need to take many measurements over a period of time, such as lighting designers, photographers, and graphic designers. By eliminating the need for manual adjustments, the Minolta CS 200 can save a significant amount of time and effort, allowing users to focus on their work instead of calibrating their equipment.

Furthermore, the Minolta CS 200’s auto-calibration system is designed to be user-friendly, allowing users to easily perform calibration and verification procedures with minimal training. The device can be calibrated with a single button press, and it provides clear instructions and feedback to guide users through the process.

5. Data Storage

The Minolta CS 200 device’s data storage feature is an essential aspect of its operation, allowing users to store and manage the colorimetric data obtained through its spectrophotometer. The spectrophotometer uses light to measure the reflectance of a sample at different wavelengths, generating a spectral reflectance curve. This curve is then converted into colorimetric data, which describes the color properties of the sample in terms of its tristimulus values, such as Lab* or LCh.

The device can store up to 1,000 measurement data sets, making it ideal for use in situations where large amounts of colorimetric data need to be collected, such as quality control in manufacturing or color matching in printing. The data is stored in the device’s internal memory, which is designed to be easily accessed and retrieved when needed. Users can easily navigate through the stored data, view previously measured color samples, and compare them to current measurements.

The device’s data storage feature is particularly useful when conducting repeated measurements over time, allowing users to track changes in color properties over time. Additionally, the data can be exported to a computer or other device for further analysis and processing, making it easy to share results with other stakeholders.

The Minolta CS 200’s data storage feature is a critical component of its operation, enabling users to store and manage large amounts of colorimetric data quickly and easily. This feature makes the device a valuable tool in a range of applications where color accuracy and consistency are crucial.

Popular Articles

Brendan O.

Who We Are

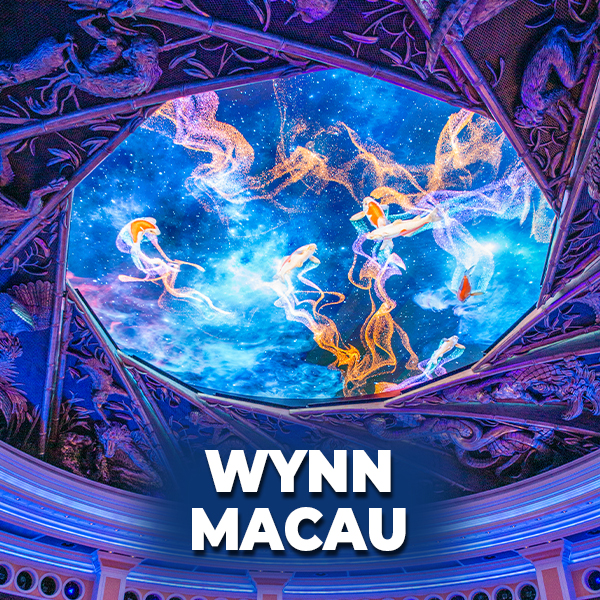

Pledco is a global reputable LED display design, engineering and manufacturer from North America, with our very own state-of-the-art production factory based in Asia. We pride ourselves on being the leading manufacturer for custom LED displays & UHD LED screens to Fortune 500 companies in over 30 countries.

WhatWe Do

We bring visual creativity to life; continually pushing the endless possibilities. From transparent mesh curtains overlaying corporate skyscrapers, to LED-wrapped vehicles, to concave video walls in newsrooms, to outdoor digital signs composed of 3D shapes; if you can envision it, our LED engineers can design, engineer and manufacture it.

How We Do It

Client’s approach us daily with “impossible” projects in terms of production and integration. At Pledco we take your design concept and apply our world-class engineering to bring your idea to life. The art of custom LED display dances in the details, and our extensive experience with custom client projects is hard to deny.

Our Customized Projects

A global reputable LED display design, engineering and manufacturer based in North America, with our very own state-of-the-art factory based in Asia. We pride ourselves on being the leading manufacturer for custom design LED displays & Ultra High Definition LED screens to Fortune 500 companies in over 30 countries.